Hardinge has been the definitive choice globally for machine tools and accessories for over 130 years. For your turning center applications, there can only be one choice: the Hardinge choice: America’s machine tool company since 1890. No matter the application, Hardinge offers a variety of turning centers which will meet and exceed your machine tool requirements for the most demanding applications in manufacturing today.

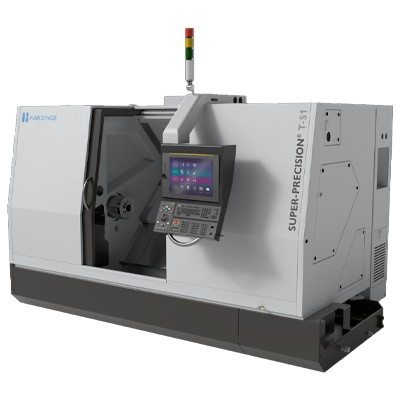

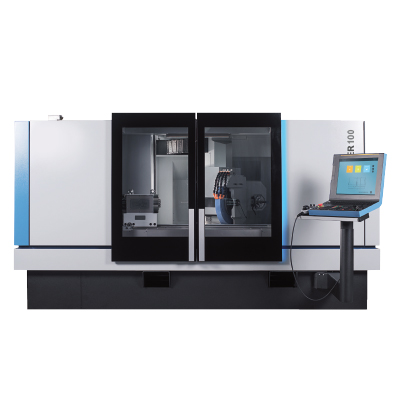

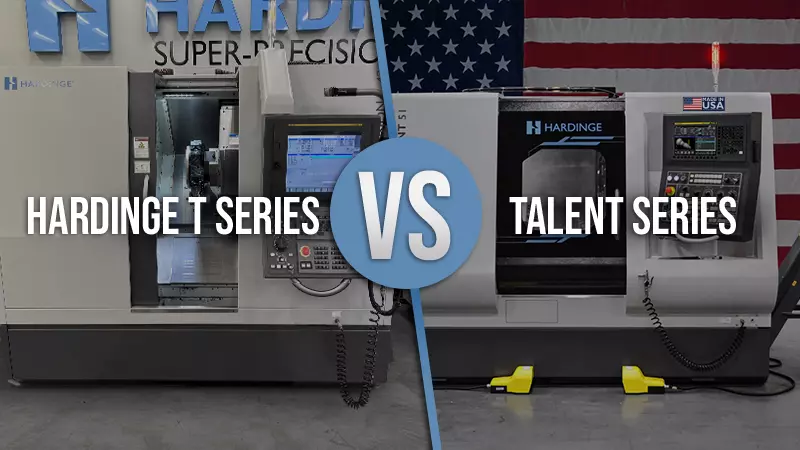

Turning centers, commonly known as lathes, are machines in which the material being processed rotates in a spindle while a fixed cutting tool passes over and removes the material until a finished shape is formed. Two of our most popular CNC turning centers, the SUPER-PRECISION® T Series and the general precision TALENT Series, have consistently exceeded consumers’ expectations, and have received unanimous critical acclaim for their extensive turning capabilities in precision applications since their release. One of the most frequently asked questions when deciding between these two industry-leading machines is, “How do I choose which one best suits my needs?”

The Hardinge SUPER-PRECISION® T Series of machines is offered for those who require the utmost in precision parts machining. Hardinge is among one of the very few machine tool manufacturers worldwide that is capable of producing SUPER-PRECISION® style machines, resulting in machines which the user can be completely confident that their end part results will meet and exceed the tightest tolerances. Our T Series machines, equipped with the industry-leading FANUC 31iTB control system with .0001mm resolution, are capable of hard turning exotic materials, including carbide, at tolerances exceeding under a micron (0.15-0.25 Ra finish), making them the ideal choice for applications demanding super precision tolerances. Gauging, defense, optics, tooling manufacturing, fuel systems, hydraulics, bearings, weapons and guidance systems, medical, automotive, mold/die, aerospace, and more, are all ideal applications for SUPER-PRECISION® technology. Hard turning also offers other benefits: it’s less costly, faster, and more economical than comparable grinding solutions, while maximizing tool life and meeting the most demanding SPC requirements. T Series machines can be purchased in three collet ready spindle configurations: 42mm, 51mm, and 65mm. All three can be produced with Y axis, live tooling, tailstock and sub spindle offerings, and can be optioned with numerous accessories including auto door, parts catcher on the main and sub spindle, in-process probe, tool probe, parts present detector, and much more. To take your most difficult and demanding turning applications to the next level, click here.

For general precision applications, look no further than the TALENT Series of machines. Featuring the most advanced FANUC 0i-TF PLUS control system, these machines are ideal for large volume, highly competitive turning operations at tolerances of +/-10 μm. They can be configured in two variations—the TALENT 42, featuring a 42mm collet ready spindle, and TALENT 51, featuring a 51mm collet ready spindle; they can also be configured with live tooling, Y-Axis, tailstock, or sub-spindle. TALENT Series machines can be ordered with various options, including but not limited to a robot interface, chip conveyor, high-pressure coolant system, tool touch probe, and more. To learn more about how our TALENT Series machines can work for you, click here.

Ultimately, the choice between the SUPER-PRECISION® T Series and the TALENT Series machines will come down to your immediate application requirements for precision. In many cases, it may be advisable to plan for the future as your operations and demands for increased precision grow. Speak with your Hardinge sales representative, distributor or one of our knowledgeable applications engineers today to learn about the benefits of taking your turning requirements to the next level with America’s machine tool company—Hardinge.

About Hardinge, Inc.

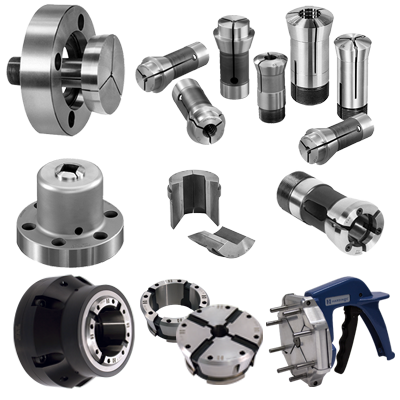

Hardinge Inc. is a leading international provider of advanced metal-cutting solutions. Headquartered in Atlanta, GA, Hardinge Inc. offers a full spectrum of highly reliable CNC turning, milling, and grinding machines as well as technologically advanced workholding and machine tool accessories. The Hardinge Group has developed a strong global presence with manufacturing operations in North America, Europe, and Asia.

Contact: Ryan Ervin

Chief Marketing Officer & Vice President, Sales

607-378-4052(o)/607-425-6997 (c)

Ryan.Ervin@Hardinge.com