Choosing the Right Finishing Process for Your Needs in Modern Manufacturing

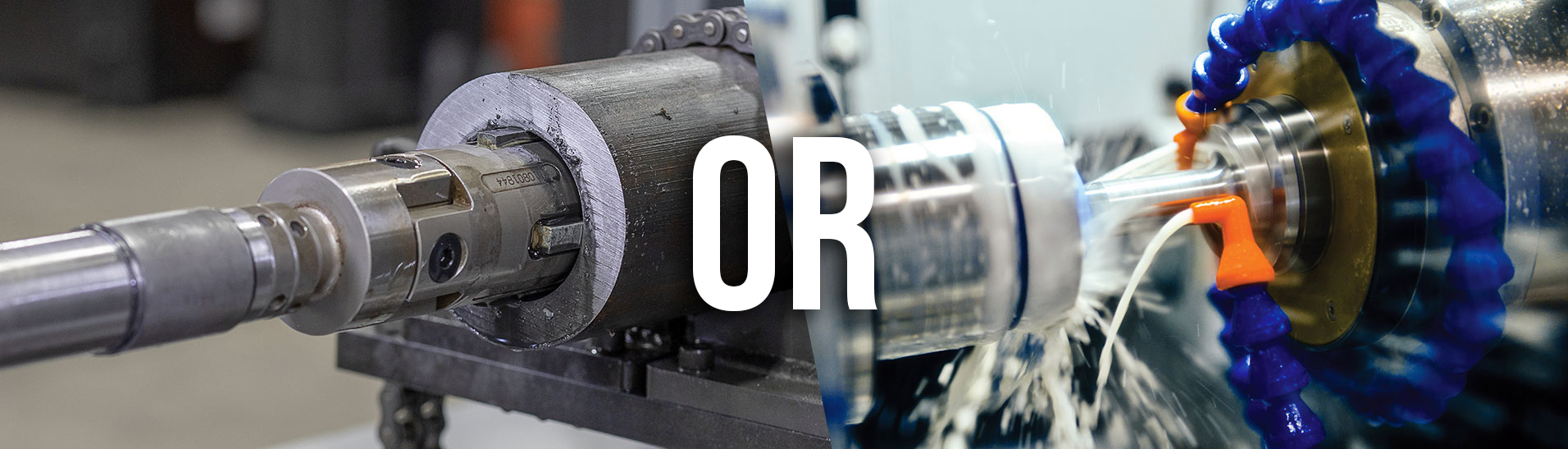

Honing and grinding are both abrasive machining processes used to improve the surface finish and dimensional accuracy of metal parts, but they differ in terms of their techniques, goals, and outcomes.

Purpose and Process

Grinding is a material removal process that involves using abrasive particles (such as grains of abrasive material like aluminum oxide or silicon carbide) to remove excess material from a workpiece. It is typically used for heavy material removal, shaping, and achieving tight tolerances and a smooth finish.

Honing is a finishing process used to improve the surface texture, roundness, and dimensional accuracy of a part under constant surface contact with the tool. It involves the use of abrasive stones or diamond hones that rotate and reciprocate within a bore or on a surface. Honing is primarily used for achieving a smoother, more precise surface finish without significant material removal.

Material Removal

Grinding is an aggressive material removal process. It removes relatively large amounts of material quickly and is suitable for tasks like stock removal and shaping. Grinding can achieve very high levels of dimensional accuracy and surface finish, making it suitable for critical applications.

Honing is a gentle material removal process. It removes only a small amount of material at a time and is designed to improve the surface finish and geometry of the workpiece without altering its dimensions significantly.

Surface Finish

Depending on the nature of the Grinding process, you could either have a rough or smooth surface. Grinding can create intricate profiles and contours that might be challenging with other machining methods. Applications can include:

- Slitting & parting

- Surface finishing

- Deburring & descaling

- Abrasive milling

- Finishing cylindrical and flat surface

- Grinding of various tools and cutters

Honing is primarily used to improve the geometric form of a surface, but can also improve the surface finish. Honing is used in applications where achieving a high-quality, internal surface finish and precise dimensions are essential, such as in engine cylinder bores, hydraulic cylinders, and gears.

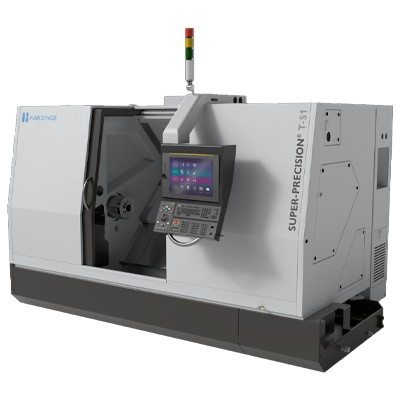

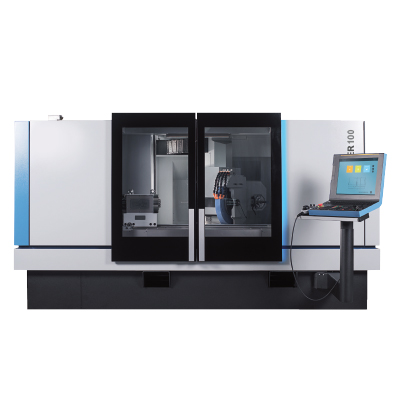

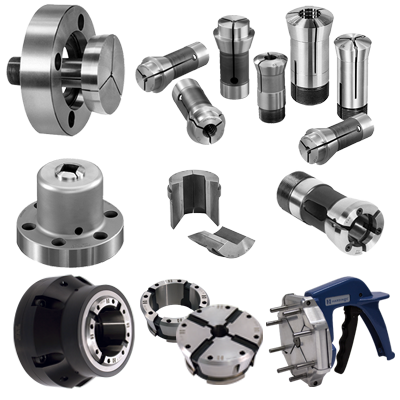

The choice between these processes depends on the specific requirements of the part and the desired surface finish and dimensional accuracy. No matter what your requirements might be, Hardinge will have either a Honing or Grinding machine for your finishing process. Our Sales and Application Engineers are here to help you answer any questions you may have.

Visit Hardinge.com for more information or to contact us on a specific machine.